Condições Imperdíveis da Black November Aqui! 🔥

In this article we will talk a little about emergency lighting systems in industrial premises, especially the importance of building an escape route lighting project and its best practices.

We will also point out some solutions and the main characteristics to be evaluated when specifying the emergency luminaire for your project.

Emergency lighting system, how important is it?

An emergency lighting system, or escape route, is necessary to guide people from inside an environment to a safe exit in cases of emergency or power outage.

When we talk about an emergency lighting system in industrial facilities, we must follow standards established by NBR 10898. Furthermore, the project developed must meet the particular characteristics of each industrial plant, considering size, exits, stairs, occupancy rate and production characteristics .

And, it’s important to remember that this project is mandatory!

This type of escape route project is carried out with the help of specialized and accredited companies, meeting all the standards required by the fire department.

Emergency lighting system and its characteristics.

There are two types of lighting: Marking and Brightening.

In this article we will focus on the lighting system that aims to illuminate the floor, a system that is compulsory on exit routes to the outside of the environment.

The recommendation regarding power is related to the environment in which the project will be developed. Lighting intensity is measured in lux, which is the ratio of the amount of lumen (luminous flux unit) per m² of space to be illuminated. In the case of new plants, the ideal is to prepare a lighting project developed by professional designers.

The lighting project is ideal for ensuring compliance with standards regarding the desired lux, especially the well-being and safety of employees, in addition to guaranteeing the specification of the appropriate luminaire in relation to the environment.

According to the ABNT NBR 10898 standard, defining the lighting system, 3 types of power sources are accepted: a set of autonomous blocks, a centralized system with rechargeable batteries or a centralized system with a motor-generator group.

Systems with autonomous blocks and rechargeable batteries are lightweight and easy to install equipment, whereas the centralized system with a motor-generator group requires compliance with a series of standards regarding its installation.

Let’s focus on the first options, and comment on their solutions and characteristics that are important to evaluate when choosing an emergency luminaire for an industrial environment.

Autonomous Block

Battery type, autonomy, warranty and maintenance. These are the main points of attention when choosing an autonomous emergency block for an industrial environment.

We bring here our Juruvaúva Line • CLK line

A point worth highlighting is maintenance, when it comes to batteries, the ideal is to have a periodic testing period, recommended every 3 months. So that the battery is discharged and recharged again so that it remains active to guarantee its perfect functioning.

An exclusive feature of Conexled’s Juruvaúva line is the SVF system – Operation Verification System. Resource integrated with an electronic source that periodically performs an operating simulation by testing and identifying battery faults (connection and autonomy), also testing the lighting LEDs and the control center (electronic source)

Another particularity of Conexled’s Juruvaúva line, autonomous block, is the option of supplying it with a light sensor.

The LDR system works as a light dependent resistor (LDR) which will only allow activation in 2 situations, during the SVF functional test or the lack of electrical supply in the condition of lack of light in the environment. Solution to increase your autonomy and save on battery consumption.

Personalização

Escape route projects for industries require greater customization, because as we mentioned at the beginning of the text, it is necessary to be appropriate in relation to their areas and production processes.

With this in mind, Conexled offers an emergency module solution in several of its lines already consolidated in the industrial market, ensuring the adequacy of the emergency lighting system project in a single solution. Reducing additional costs with parallel systems, and ensuring the robustness required according to the production process of each type of segment, providing a large reduction in maintenance costs with above-market guarantees.

See some options below:

TIMBÓ LINE – CLT-E

LED luminaire for TGVP areas

With emergency module

10W emergency mode

3 year warranty

Autonomy: 120 minutes

Full Recharge Time: 24 hours

BORACEIA LINE – CLB-E

Hermetic luminaire with module

of emergency.

10W emergency mode

3 year warranty

Autonomy: 90 minutes

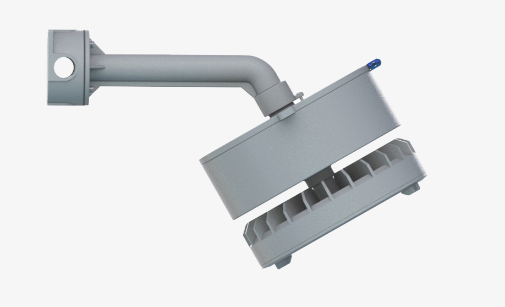

PEREQUÊ LINE – CLY-E

Luminaire for Explosive Atmospheres

With Emergency Module.

10W emergency mode

3 year warranty

Autonomy: 120 minutes

Full Recharge Time: 24 hours

Did you like this content?

So like and share so that more companies can make the best choice for their operations!

Talk to a specialist now and find out which emergency lighting system is best suited for your project

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.