Condições Imperdíveis da Black November Aqui! 🔥

Industrial lighting projects are quite complex, as they have several different areas within the same complex, such as places with great heights, machinery that has high vibration, environments with temperature variations, fluctuations in the electrical network, etc…

There are also industrial areas that require products with additional protection, such as environments with a high incidence of gases, vapors, dust and weather installation.

For this type of project in industries, the ideal are luminaires that have versatility in their installation, display with special lens options according to the customer’s needs, long useful life as any stop for replacement or maintenance impacts the company’s business, material of the resistant luminaire body with special painting, ensuring that the degree of protection and impact are in accordance with the needs of the project.

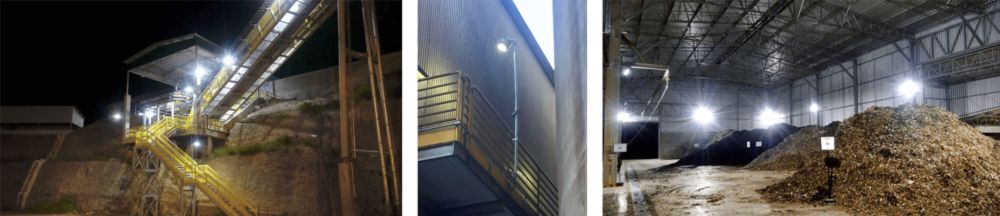

Here we present examples of projects that used LED luminaires from Conexled’s Timbó line.

The projects we will present below had something in common: they required luminaires with different installation options. In the project of a port terminal, there was a need for a luminaire for installation on a pole and a product for installation on a wall light, which were resistant to the weather. This same need was seen in the project of an agro industry, where they needed a product that could be installed in an internal area of the industry and another that had the installation for a pole, both with a degree of protection that was suitable for an environment with emission of gases, dust and vapors and also that they had a special painting to avoid corrosion as they would be installed over time. In a cement industry, the need was for a luminaire to be installed in a warehouse and also to have the option of being installed in an external area fixed to a pole and in the conveyor belt area.

So, for projects like these, the LED luminaire from the Timbó line was the most suitable as it has different types of installation, is compact and very efficient, has an IP66 degree of protection and fixes the covers through threading and a flexible silicone gasket for high temperatures, body made of cast aluminum with high mechanical resistance, corrosion and efficient thermal dissipation, ensuring greater durability of the useful life of the LED and the power supply (driver). In addition to all these advantages, the line has a useful life of up to 100,000 hours and a three-year warranty.

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.