Condições Imperdíveis da Black November Aqui! 🔥

In the oil and gas industry, implementing strict safety measures is imperative to prevent accidents in explosion-prone environments. A critical aspect of this safety is the choice and use of certified EX luminaires. This article explores the technical and regulatory importance of certifying these luminaires, emphasizing the standards and practices that ensure operational safety and regulatory compliance.

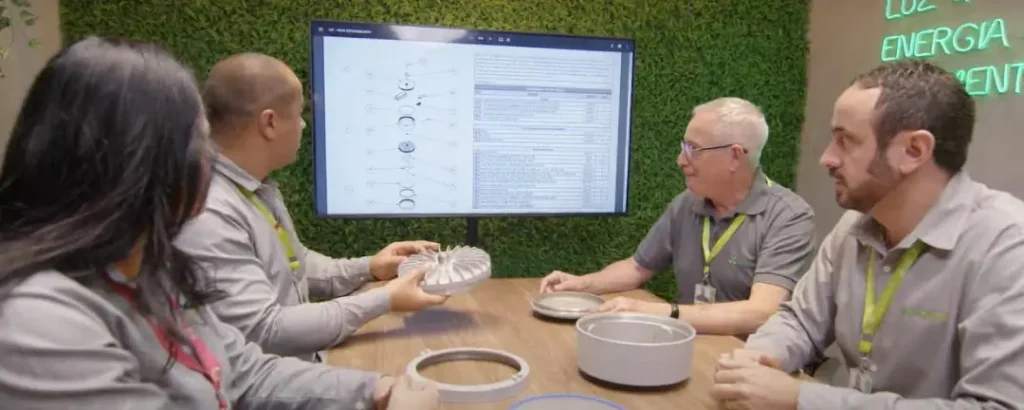

Certified EX luminaires are designed to operate safely in locations where the presence of flammable elements such as gases, vapor, dust, or fibers can result in explosions or fires. These devices undergo rigorous testing to ensure they can contain and isolate internal sparks or arcs, preventing the ignition of surrounding explosive atmospheres.

The certification of these luminaires follows strict international and regional standards, such as:

Luminaires for explosive atmospheres are built with additional measures that ensure safety for installation in explosive atmospheres. Besides mechanical strength, these luminaires have advanced sealing systems to ensure an IP protection grade against the entry of solid objects and liquids, and thermal control systems to keep the operational temperature within safe limits.

When selecting EX luminaires, it is crucial to consider:

The certification of luminaires for explosive atmospheres is a critical component in ensuring safe and efficient operations in the oil and gas industry. Adopting certified luminaires not only complies with legal requirements but also represents a significant investment in operational safety and environmental protection. The entities involved must prioritize regulatory compliance and technical quality in choosing these lighting solutions.

External References:

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.