Condições Imperdíveis da Black November Aqui! 🔥

When planning lighting for a food and beverage industry, some important factors should be considered according to the area of application. Carefully planned industrial lighting reduces the risk of accidents, such as broken glass falling on people or food.

But how do you know which is the ideal option for these environments?

In washing areas in the food industry, it is essential to opt for LED luminaires and other accessories with the correct protections. For example, where there are exposed products such as meat, make sure that the equipment has the appropriate protection for washing areas. Also be aware of the requirements and standards of the lighting regulations for these areas.

In warehouse aisles, LED lighting in the linear option is an excellent choice due to its high durability, natural, homogeneous lighting and its high brightness index. It can also be a very economical option, as it makes it possible to fit motion detectors in the luminaires so that when forklift trucks are moving through the aisles, the lighting becomes brighter and dims once the vehicles have passed.

Longer luminaire life – LED luminaires from reliable companies last up to 10 years before requiring replacement. This allows installations in hard-to-reach places, such as over equipment, without worrying about interrupting production schedules.

Low maintenance costs – Due to the longer life of the luminaire, LED lighting requires less maintenance than other types of lighting, allowing your plant to continue operations with fewer interruptions from service staff.

Ability to withstand cold conditions – LED lighting works especially well in colder conditions, such as freezer warehouses, unlike fluorescent lighting, which is more sensitive to extremely low temperatures, causing breakdowns.

Considering all these fundamental factors when choosing the ideal LED luminaire, cost certainly shouldn’t be the most important issue when making a purchase, since in the long term, inefficient lighting can represent a huge expense for the industry, both in terms of energy consumption and the replacement and maintenance of luminaires and other elements of the system. That’s why investing in high-performance LED lighting is the best option that only qualified companies who understand quality lighting can offer!

Discover the Conexled luminaires suitable for lighting in the food industry:

The hermetic Industrial LED luminaires of the Boracéia line guarantees resistance, versatility and optimum performance for applications in the food industry, saving energy and substantially reducing maintenance cycles. The installation of this product is directly on the ceiling or profile, suitable for use in places subject to non-flammable gases, dust, vapors and powders, or areas that require continuous cleaning using water, as it has IP66 degree of protection.

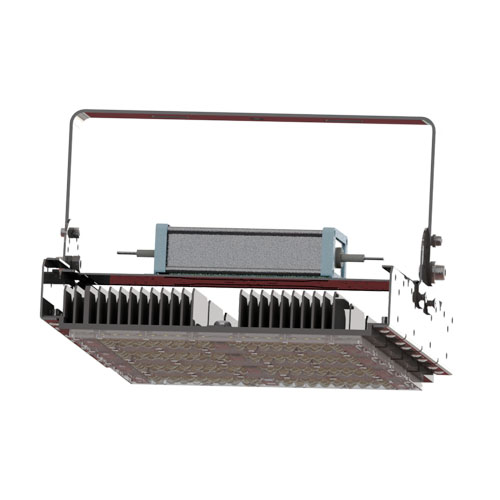

The Itararé safe for food installations as it has been designed for use in hazardous areas in Zones 2, 21 and 22, with Ex nC nR type of protection, without the need to carry out a restricted breathing test in the field at the time of installation. It has a body made from injected aluminum alloy with high mechanical and corrosion resistance, with efficient thermal dissipation, guaranteeing longer life for the LED and the power supply (driver).

The High Bay industrial luminaires from the Picinguaba Conexled’s Picinguaba range provide optimum performance, versatility and robustness for applications in warehouses, storerooms, storerooms, hangars and pendant installations up to 15 meters high. With its intelligent light sensor, the Picinguaba range saves up to 40% compared to traditional Led high bay luminaires. The user can set the intensity of light they want in the room and the luminaire will automatically compensate for external light (e.g. sheds with skylights or side windows), reducing consumption during the day without making the room dark or out of line with the norm.

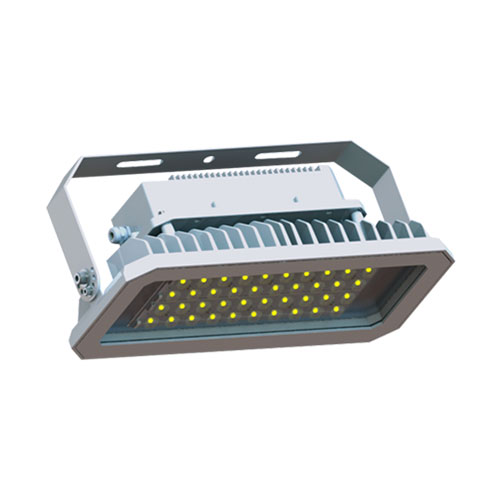

The Indaiá LED floodlights line have a modular system that makes maintenance easy and provide optimum performance for lighting in filling and finished product areas. With a modern, bold design and high mechanical resistance, the line stands out for its easy installation and low weight.

Click here to see and see more options for lighting in the food industry.

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.