Condições Imperdíveis da Black November Aqui! 🔥

When planning the lighting for a paper and cellulose industry, some important factors must be considered according to the area of application and each environment. Carefully planned industrial lighting reduces the risk of accidents, saves energy and makes better use of the entire industrial process.

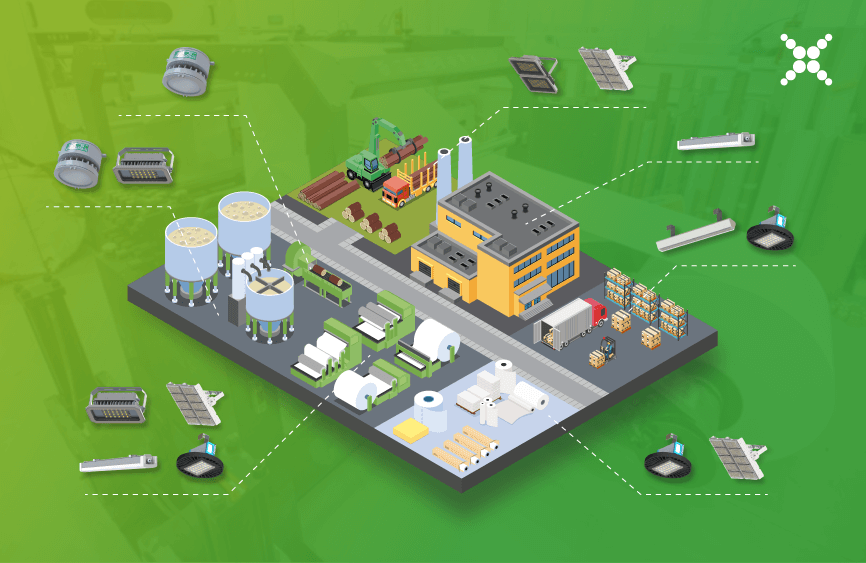

For each production process in the paper and cellulose industry there are specific luminaires. Below are some examples of environments and models (click on each product to download the datasheet):

It is also worth remembering the importance of carrying out a lighting project to better define the product, taking into account the particularities of the environment.

Still have questions or need more information? Get in touch right now and speak to a Conexled consultant!

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.