*Adapted from Roberval Bulgarelli’s talk.

In environments with explosive atmospheres, such as oil refineries, oil platforms and agro industries, safety is paramount at all stages of the installations’ life cycle.

This article explores the importance of certifying professionals and companies at all stages, from acquisition to maintenance to avoid serious accidents.

In places where flammable gases and dust are present, such as oil refineries and offshore platforms, agro-industries and chemical industries, the risks of explosions are significant.

The consequences of an incident can be devastating. To ensure safety in these areas, it is essential to adopt strict measures at all stages of the life cycle of installations in explosive atmospheres.

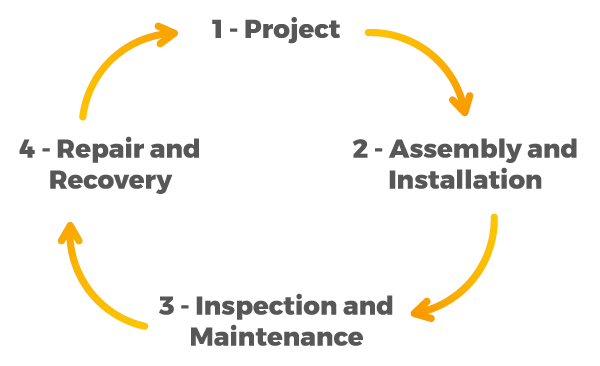

This is the entire period in which the equipment is in operation in a classified area.

The first phase of an installation’s life cycle is design. It is crucial that the engineers and designers who develop the installations understand the technical standards applicable to hazardous areas.

They must design electrical systems, equipment and structures in accordance with these standards. Certification of professionals ensures that they have the necessary knowledge to carry out this work.

During the assembly and installation phase, the companies responsible for these tasks need to ensure that the equipment is installed correctly and in compliance with standards.

Certification of service companies guarantees that they have quality management systems and skills to carry out these activities.

Regular maintenance and thorough inspections are essential to ensure the integrity of the facility. Certified professionals can carry out visual and detailed inspections, as well as maintenance activities in accordance with technical standards.

Certification ensures they have the skills needed to perform these tasks safely.

When equipment or facilities need repair or restoration, it is essential that repair service companies are certified.

This ensures that repairs are carried out according to regulations and that safety is maintained during the process.

Specific technical standards for hazardous areas provide detailed guidelines for designing, installing, inspecting and maintaining facilities. To ensure compliance with these standards, there are certification systems that assess the competence of professionals and companies.

The International Personal Competence Certification System, known as IECEx, covers several areas, from area classification to detailed inspections.

Although regulatory standards, such as NR-10 (Regulatory Standard for Electrical Safety), are important for safety, they have a limited scope and do not cover all the needs of hazardous areas. Therefore, more comprehensive certification systems are needed to fill security gaps.

Companies began to include certification requirements in their contracts, driving the market to seek compliance with standards and certification systems. This raises the safety standard in the facilities and protects against serious accidents.

To ensure safety at all stages of the life cycle of installations in hazardous areas, certification is essential. This involves the certification of professionals and companies, ensuring that everyone has the knowledge and skills necessary to comply with technical standards.

It is an essential step in the search for safety and the prevention of serious accidents in explosive atmospheres.

If you want to know more about Lighting for Explosive Atmospheres, check out Episode 3 of LEDCast, with the special participation of Roberval Bulgarelli and Mauro Noda:

CNPJ 54.601.612/0001-69

Conex Eletromecânica Ind e Com Ltda.

A Conexled procura constantemente novos fornecedores para seus negócios.

Se você tem interesse em ser um de nossos parceiros, preencha o formulário abaixo.

Quer ser um representante da Conexled?

Se você tem interesse em ser um parceiro da marca, preencha o formulário abaixo.

Ficou com alguma dúvida, ou precisa de ajuda para escolher a melhor solução para seu projeto?

Fale diretamente com um de nossos consultores.